Content

STANDARD PLASTIC PALLET

What is standard plastic pallet?

Plastic pallets are widely used in today's market. With a wide variety of industries. To be able to consume so much. Plastic pallets need to meet basic product quality standards. So what are these standards? Find out in the comments below.

Product quality standards

A plastic pallet product used is a plastic pallet that must meet product quality requirements. Product quality requirements include:

Standard plastic pallet material

Plastic pallets must be manufactured from standard plastic materials such as HDPE or PET, etc. These are durable plastic materials. Good resistance. And not affected by environmental factors.

Specifications of standard plastic pallets

- Plastic pallets must have the following characteristics:

+ High durability

+ Waterproof

+ Anti-termite

+ Doesn't get moldy

+ Insulation

+ Insulation

+ Thin and light

+ Safe to use

+ No harm to the environment

Size

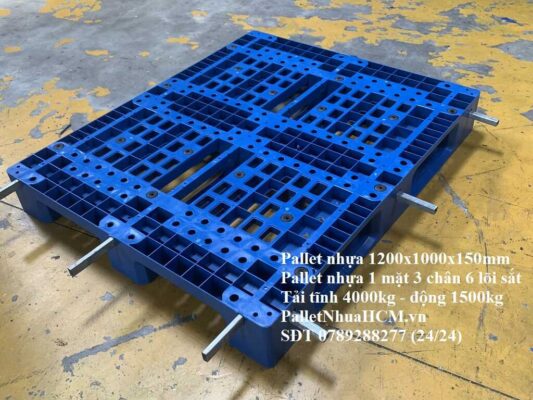

Standard plastic pallets are manufactured in a wide variety of sizes. Suitable for different uses. On the current market, there are a number of standards for plastic pallet sizes as follows:

-

Dimensions 1000 x 1000 x 150 mm

-

Dimensions 1100 x 1200 x 150 mm

-

Dimensions 110 x 1100 x 120 mm

-

Dimensions 800 x 1200 x 180 mm

- Dimensions 1000 x 1000 x 135 mm

- Dimensions 1200 x 900 x 135 mm

- Dimensions 1100 x 1100 x 140 mm

These standard sizes will be suitable for each type of product that plastic pallets transport or store. Depending on the use and purpose of use. Customers can choose from different sized plastic pallets to use.

Color

Quality standard plastic pallets are plastic pallets that need the right color according to the design. The color reflects the quality status of the plastic pallet. So looking at the color we can assess the condition of the plastic pallet.

- If the color of the plastic pallet is fresh and bright. It means that the plastic pallet is new and manufactured from good, standard materials.

- If the plastic pallet has faded or faded. That is, the product is old, used many times or manufactured from bad plastic.

Thus, based on the color, it is possible to assess the condition and quality of the plastic pallet.

Design

Standard plastic pallets are plastic pallets manufactured according to the design. Design is the basis for plastic pallets to be manufactured in the right size, style and design.

- Plastic pallets, if manufactured according to the design, will be effective when used.

- If not manufactured to the right design, plastic pallets may not be able to withstand the load when transporting or storing goods. Besides, it can also cause damage when the size and design are not up to standard.

Therefore, it is necessary to meet design standards for plastic pallets to be accepted for use and achieve the best use.

Production process

Plastic pallets are manufactured by many different companies. However, the production process all need to follow the following steps:

Preparations:

This is the first step in the production process. With good preparation, the next production steps will take place easier.

Finishing mold making:

Plastic pallets will be molded according to designs and molds available according to production lines at factories.

Spray label:

Labels are inkjet printed at the request of customers to help identify plastic pallets and promote the company name.

Antiseptic:

For plastic pallets, fumigation is quite simple. The plastic pallets after production will be fumigated before being warehoused.

Finished products warehouse:

This is the final step in the plastic pallet manufacturing process. Plastic pallets are stocked to prepare for sale or delivery to customers.

Some notes in the production of plastic pallets:

+ Plastic pallets will usually not be easy to repair because they are manufactured according to a certain line and process.

So these products are often used by logistics providers who can profit from high strength plastic pallet products.

+ Large supply companies have increased the use of plastic pallets as a way to reduce costs through transportation, waste, health and safety.

+ The production of plastic pallets is often important in size, design, style, color, and load.

+ Export plastic pallets can be changed according to the requirements of customers according to the standards given by ISO.

Therefore, with each different plastic pallet manufacturing company, there will be different regulations and production methods.

As such, for a plastic pallet product to be accepted, it must meet the requirements of standards for quality, color, size, design and manufacturing process. Meeting these standards, plastic pallets will be eligible to put into use and serve the activities of transporting, loading and unloading and storing and preserving goods.